Vinocon RO1 Series

Vinocon RO1 Series

Wine Processing – Grape Juice & Must Concentration

The Vinocon family of proprietary thin-film reverse osmosis membrane elements are characterized by high sodium chloride rejection and a smooth, fouling-resistant membrane surface. The S-Series membrane has an average rejection of 98.5% on 2,000ppm NaCl at 25°C and 225psi operating pressure.

The Vinocon RO1 Elements provide high rejection of sugars and low molecular weight organic constituents. This element is designed for high crossflow, daily CIP and the ability to handle suspended solids and periodic hot-water sanitation, while still maintaining element integrity. They are typically used for concentrating grape must in wineries requiring stringent sanitary procedures. Other applications may include grape juice concentration and wine adjustment.

The Vinocon RO1 Elements feature a Durasan* Cage patented outer wrap, and standard feed spacers and polysulfone parts.

Table 1: Element Specification

Membrane A-series, thin-film membrane (TFM*)

| Model | Spacer mil (mm) | Active area ft2 (m2) | Part Number |

|---|---|---|---|

| Vinocon RO1 4040C30 | 30 (0.76) | 80 (7.4) | 1230053 |

| Vinocon RO1 4040C50 | 50 (1.27) | 65 (6.0) | 1265750 |

| Vinocon RO1 8040C35 | 35 (0.89) | 343 (31.9) | 1230055 |

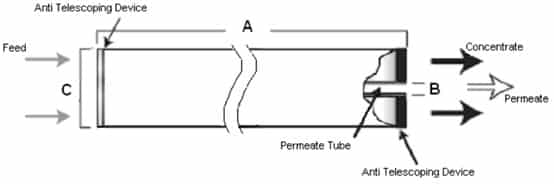

Table 2: Dimensions and Weight

Dimensions, inches (cm)

| Model1 | A | B2 | C3 | Boxed Weight lbs(kg) |

|---|---|---|---|---|

| Vinocon RO1 4040C30 | 40.00 (101.6) | 0.625(1.59) | 3.98(10.1) | 7 (3.2) |

| Vinocon RO1 4040C50 | 40.00 (101.6) | 0.625 (1.59) | 3.98 (10.1) | 7 (3.2) |

| Vinocon RO1 8040C35 | 40.00 (101.6) | 1.125 (2.86) | 7.91 (20.1) | 29 (13.2) |

- These elements are dried and bagged before shipping.

- Internal diameter.

- The element diameter (dimension C) is designed for optimum performance in GE Water & Process Technologies pressure vessels. Others pressure vessel dimension and tolerance may result in excessive bypass and loss of capacity.

Table 3: Operating and CIP parameters

| Typical Operating Pressure | 200 – 800psi (1,379 – 5,516kPa) |

| Typical Operating Flux | 5-20 GFD (8-34 LMH) |

| Clean Water Flux (CWF)1 | 14 GFD (24 LMH) @ 225psi |

| Maximum Operating Pressure2 | 1,200psi (8,276kPa) |

| Maximum Temperature | 122°F (50°C) |

| Sanitization Temperature | 194°F (90°C) |

| pH Range | 3.0-10.0 |

| Maximum Pressure Drop | Over an element: 15 psi (103 kPa) Per housing: 60 psi (414 kPa) |

| Chlorine Tolerance | 500 ppm-hours dechlorination recommended |

- Clean water flux (CWF) is the rate of water permeability through the membrane after cleaning (CIP) at reproducible temperature and pressure. It is important to monitor CWF after each cleaning cycle to determine if the system is being cleaned effectively. CWF can vary ±25%.

- Operating pressure in bar multiplied by operating temperature in degree Celsius should not exceed 2000.

Table 4: CIP limits for RO elements

| Temperature | pH minimum | pH Maximum |

|---|---|---|

| 50°C (122°F) | 2.0 | 11.5 |

| 45°C (113°F) | 1.5 | 11.5 |

| 35°C (95°F) | 1.5 | 11.5 |

| 25°C (77°F) | 1.0 | 12.0 |

HOT WATER SANITIZATION RECOMMENDATIONS

For optimal performance, Duracon RO5 elements should always be cleaned using approved CIP procedures and flushed with fouling free water before the sanitization process. Feed pressure during sanitization should not exceed 40psi (275kPa) and the crossflow should not incur a pressure drop greater than 2psi (14kPa) per element. Heating rate to sanitizing temperature and cool down should not be faster than 5°C/minute. Maximum sanitization temperature is 90°C.

LOSS OF PERMEATE FLOW AFTER REPEATED 90°C SANITIZATION CYCLES

It is almost impossible to exactly predict the percentage of permeate flow rate lost from the high temperature sanitations, which among other factors depends on:

- Rate of temperature increase and decrease.

- Presence of other species like organics, ionic and metallic compounds that could locally decrease or increase the temperature at the surface of the membrane.

- Feed flow rate and specifically the heat transfer rate to the membrane surface.

- The thickness and geometry of the feed spacer used.

At optimum conditions measured in controlled environment with deionized water, around 30% of the original permeate flow rate was lost before the element performance had stabilized after repeated heat treatments (over 90% of this flow reduction occurred during the first heat treatment). With the loss of permeate flow rate, the salt rejection increases. The rate of cooling and heating was not more than 5°C per minute, and the differential pressure drop per element did not exceed 2 psi. Pilot testing based on the criteria noted above will give the best operating parameters for any specific application.