AG HR Series

AG HR Series

High Rejection Brackish Water RO Elements

GE Power Water & Process Technologies

The A-Series family of proprietary thin-film reverse osmosis membrane is characterized by high flux and high sodium chloride rejection. AG HR brackish water elements are selected when high rejection and operating pressures as low as 200 psi (1,379 kPa) are desired. These elements are recommended for brackish water with salt concentration (TDS) levels between 1,000 and 10,000mg/l or when very high salt rejection of monovalent ions is required.

Table 1: Element Specification

Membrane Thin-film membrane (TFM*)

| Model | Average permeate flow gpd (m3/day)1,2 | Average NaCl rejection1,2 | Minimum NaCl rejection1,2 |

|---|---|---|---|

| AG-90 | 2300 (8.7) | 99.8% | 99.3% |

| AG-365 | 10,000 (37.9) | 99.8% | 99.3% |

| AG-400 | 11,000 (41.6) | 99.8% | 99.3% |

| AG-400, 34 | 11,000 (41.6) | 99.8% | 99.3% |

| AG-440 | 12,000 (45.4) | 99.8% | 99.3% |

1 Average salt rejection after 24 hours operation. Individual flow rate may vary +/-20%.

2 Testing conditions: 2,000ppm NaCl solution at 225psi (1,550kPa) operating pressure, 77°F (25°C), pH7 and 15% recovery.

| Model | Average permeate flow gpd (m3/day)1,2 | Average NaCl rejection1,2 | Part Number |

|---|---|---|---|

| AG-90 | 90 (8.4) | Fiberglass | 3056665 |

| AG-365 | 365 (33.9) | Fiberglass | 3056666 |

| AG-400 | 400 (37.2) | Fiberglass | 3056667 |

| AG-400, 34 | 400 (37.2) | Fiberglass | 3056668 |

| AG-440 | 440 (40.9) | Fiberglass | 3056669 |

Table 2: Operating and CIP parameters

| Typical Operating Pressure | 200 psi (1,380 kPa) |

| Typical Operating Flux | 10-20GFD (15-35LMH) |

| Maximum Operating Pressure | 600 psi (4,137 kPa) |

| Maximum Temperature | Continuous operation: 122°F (50°C) Clean-In-Place (CIP): 122°F (50°C) |

| pH range | Optimum rejection: 7.0-7.5, Continuous operation 4.0-11.0, Clean-In-Place (CIP): 1.0-13.01 |

| Maximum Pressure Drop | Over an element: 12 psi (83 kPa) Per housing: 50 psi (345 kPa) |

| Chlorine Tolerance | 1,000+ ppm-hours, dechlorination recommended |

| Feedwater2 | NTU < 1 SDI < 5 |

1 Please refer to Cleaning Guidelines Technical Bulletin TB1194

2 SDI is measured on a non-linear scale using a 0.45 micron filter paper. Additionally, finer colloids, particulates and microorganisms that pass through the filter paper and not measured in the SDI test, will potentially foul the RO element. For performance consistency and project warranty, please use Winflows projection software and consult your GE representative.

Table 3: Dimensions and Weights

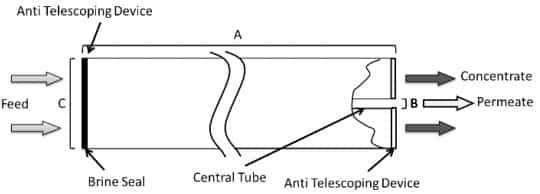

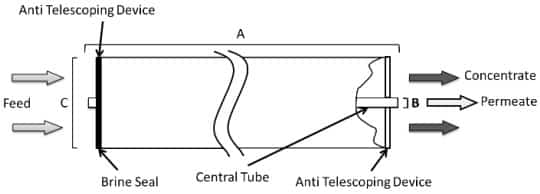

A,B,C Dimensions, Inches (cm)

| Model | Type | A | B | C | Boxed Weight lbs (kg) |

|---|---|---|---|---|---|

| AG-90 | Male | 40.0 (101.6) | 0.75 (1.90) | 3.9 (9.9) | 9 (4) |

| AG-365 | Female | 40.0 (101.6) | 1.125 (2.86) | 7.9 (20.1) | 35 (16) |

| AG-400 | Female | 40.0 (101.6) | 1.125 (2.86) | 7.9 (20.1) | 35 (16) |

| AG-400, 34 | Female | 40.0 (101.6) | 1.125 (2.86) | 7.9 (20.1) | 35 (16) |

| AG-440 | Female | 40.0 (101.6) | 1.125 (2.86) | 7.9 (20.1) | 35 (16) |